Pneumatic damper is a device that uses compressed air as a power source to control the opening, closing, or regulating of the medium flow rate through changes in air pressure.

Pneumatic damper is a device that uses compressed air as a power source to control the opening, closing, or regulating of the medium flow rate through changes in air pressure. The following is a detailed introduction about pneumatic dampers:

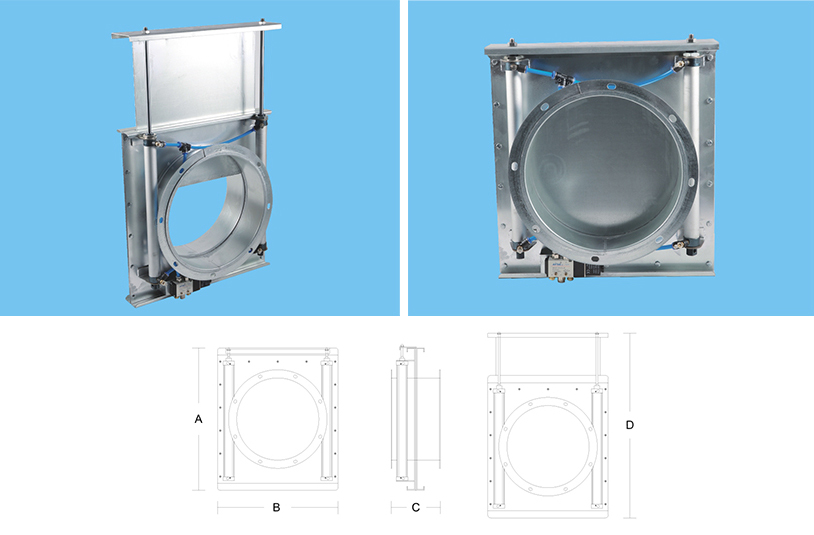

Pneumatic damper, also known as pneumatic ventilation butterfly valve, is a device for controlling the flow of air or gas in pipelines by dividing and merging or switching the flow direction.

Air supply: Pneumatic dampers require a stable compressed air source, usually provided by an air compressor and transported to the valve through pipelines.

Execution mechanism: The execution mechanism of pneumatic dampers is usually a cylinder or diaphragm actuator. When compressed air enters the actuator, it will push the cylinder piston or diaphragm to move.

Valve core action: The movement of the actuator drives the connected valve core or valve plate to move, changing the opening of the valve and controlling the flow rate of the medium.

Control signal: The operation of the pneumatic damper can be achieved through manual operation, solenoid valve control, or more complex control systems such as PLC. These control systems send signals to solenoid valves or other types of pilot valves to control the entry or exit of compressed air into the actuator.

Comments on “china weishan Pneumatic damper Characteristics and advantages”